Micro Cold Forming - Subproject A3: Material accumulation

| Working Group: | WG Numerics of PDEs |

| Leadership: | Prof. Dr. Alfred Schmidt ((0421) 218-63851, E-Mail: alfred.schmidt@uni-bremen.de ) |

| Processor: |

Dr. Andreas Luttmann

Dr. Mischa Jahn |

| Funding: | DFG |

| Project partner: | BIAS, Bremer Institut für Angewandte Strahltechnik |

| Time period: | 01.01.2007 - 31.12.2018 |

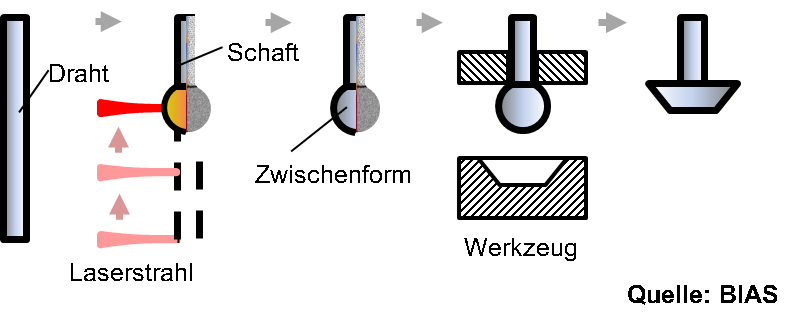

The aim of the Collaborative Research Centre 747 „Micro cold forming“ is the supply of processes and methods for the forming and technical manufacturing of metallic components that are smaller than 1mm in two dimensions. Part of the CRC 747is the subproject A3 which addresses the problem of material accumulation using laser- based free form heading. In detail, the project A3 deals with an process chain for the production of preforms for forging and sheet metal forming. Laser rod end melting enables upset ratios >>200 instead of an upset ratio of approximately 2, which can be achieved using conventionally methods.

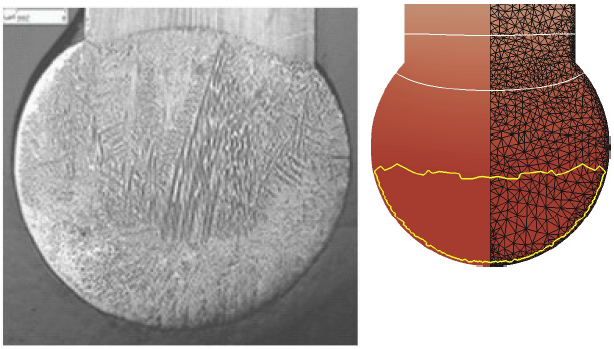

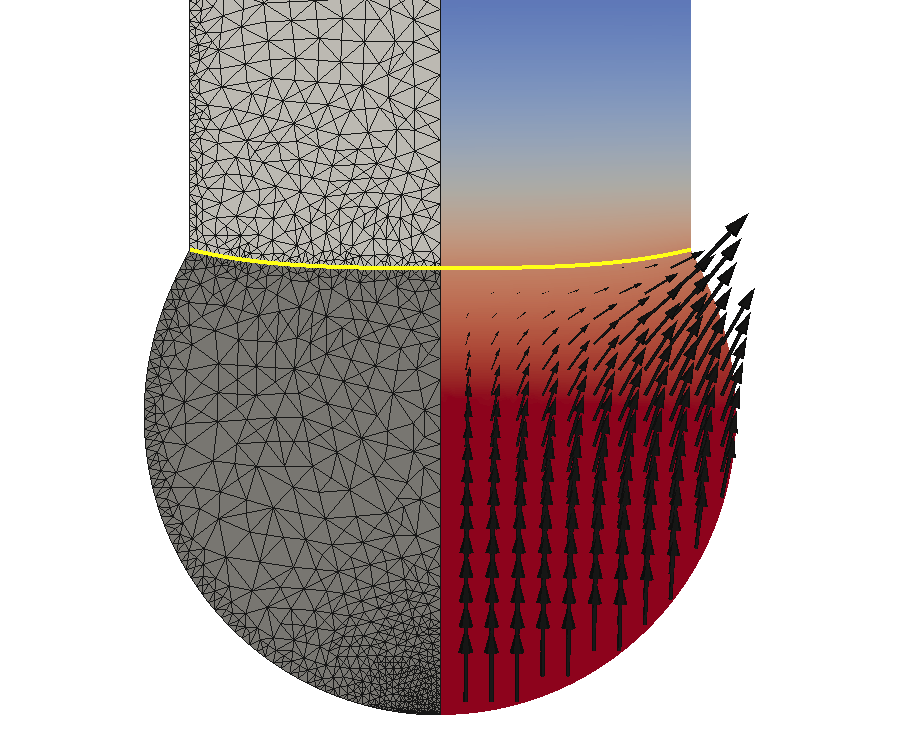

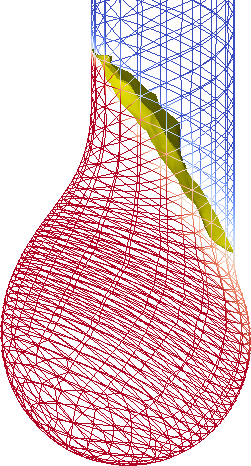

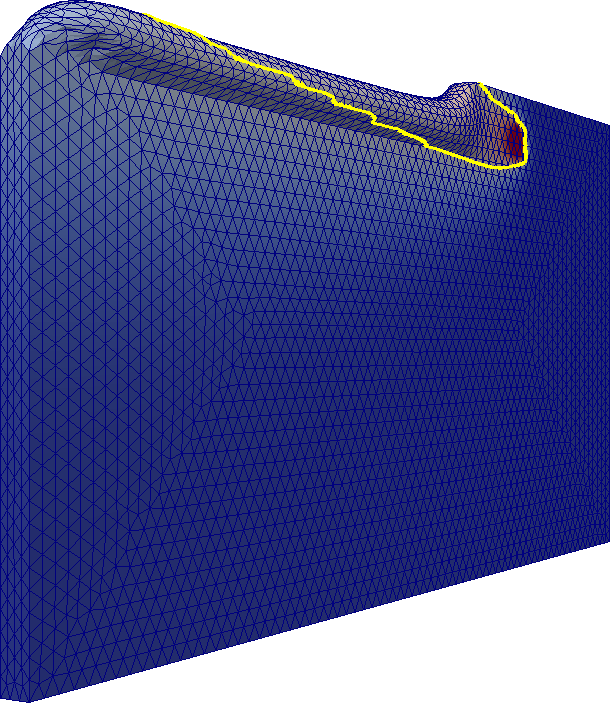

The aim of the Collaborative Research Centre 747 „Micro cold forming“ is the supply of processes and methods for the forming and technical manufacturing of metallic components that are smaller than 1mm in two dimensions. Part of the CRC 747is the subproject A3 which addresses the problem of material accumulation using laser- based free form heading. In detail, the project A3 deals with an process chain for the production of preforms for forging and sheet metal forming. Laser rod end melting enables upset ratios >>200 instead of an upset ratio of approximately 2, which can be achieved using conventionally methods. For handling the process, a finite element simulation is used to compute process parameters, e.g. laser heating duration and laser beam deflection velocity. This simulation bases on „Navier“ by E. Bänsch (University of Erlangen-Nürnberg). Navier is a finite element method for the simulation of the incompressible Navier-Stokes equations including a capillary surface which has been extended so that melting and solidification process described by the Stefan problem can be considered.

While 2D situations including 2D rotational symmetric and cross section models can already be handled, the development of a full 3D version to handle general situations is still going on.

Publications

- M. Jahn, J. Montalvo Urquizo.

Modeling and simulation of keyhole-based welding as multi-domain problem using the extended finite element method.

Applied Mathematical Modelling, 82:731-747, Elsevier, 2020. - B. Kuhfuß, C. Schattmann, M. Jahn, A. Schmidt, F. Vollertsen, E. Moumi, C. Schenck, M. Herrmann, S. Ishkina, L. Rathmann, L. Heinrich.

Micro Forming Processes.

Cold Micro Metal Forming, F. Vollertsen, S. Friedrich, B. Kuhfuß, P. Maaß, C. Thomy, H. Zoch (Eds.), Lecture Notes in Production Engineering, pp. 27-94, Springer Verlag, 2020. - E. Bänsch, A. Schmidt.

Free boundary problems in fluids and materials.

Geometric Partial Differential Equations - Part I, A. Bonito, R. H. Nochetto (Eds.), Handbook of Numerical Analysis Vol. 21, pp. 555-619, Elsevier, 2020. - E. Bänsch, A. Luttmann, J. Montalvo Urquizo, A. Schmidt, M. G. Villarreal-Marroquin.

Simulation and multi-objective optimization to improve the final shape and process efficiency of a laser-based material accumulation process.

Journal of Mathematics in Industry, 10(2), 30 p., 2020. - A. Luttmann, M. Jahn, A. Schmidt.

Modeling and Simulation Approaches for the Production of Functional Parts in Micro Scale.

Springer Mathematics in Industry Vol. 30, 51-58 pages, Springer Verlag, 2019. - M. Jahn.

miXFEM- an XFEM toolbox to tackle multiphysics problems with FEniCS.

Projektbericht, Poster, FEniCS'18 Workshop at Oxford University, März 2018. - M. Jahn.

An automated hierarchical eXtended finite element approach for multiphysics problems involving discontinuities.

Dissertationsschrift, Universität Bremen, 2018. - D. . Rippel, C. Schattmann, M. Jahn, M. Lütjen, A. Schmidt.

Application of Cause-Effect-Networks for the process planning in laser rod end melting.

ICNFT 2018.

MATEC Web Conf. , F. Vollertsen (Eds.), 190:15005, 2018. - A. Luttmann.

Modellierung und Simulation von Prozessen mit fest-flüssig Phasenübergang und freiem Kapillarrand.

Dissertationsschrift, Universität Bremen, 2018. - A. Schmidt, E. Bänsch, M. Jahn, A. Luttmann, C. Niebuhr, J. Vehmeyer.

Optimization of Engineering Processes Including Heating in Time-Dependent Domains.

27th IFIP TC 7 Conference, CSMO 2015, 29.06.-03.07.2015.

IFIP AICT Series , 494:452-461, Springer Verlag, 2017. - A. Schmidt, E. Bänsch, M. Jahn, A. Luttmann, C. Niebuhr, J. Vehmeyer.

Optimization of Engineering Processes Including Heating in Time-Dependent Domains.

IFIP AICT Series Vol. 494, 452-461 pages, Springer Verlag, 2017. - M. Jahn, A. Luttmann, T. Klock.

An XFEM toolbox for FEniCS.

Projektbericht, Poster, FEniCS'16 Workshop at Simula Research Laboratory, Mai 2016. - H. Brüning, M. Jahn, F. Vollertsen, A. Schmidt.

Influence of laser beam absorption mechanism on eccentricity of preforms in laser rod end melting.

11th International Conference on Micro Manufacturing (ICOMM), 29.03-31.03.2016, Orange County, USA.

- A. Schmidt, C. Niebuhr.

(Ideas about) Adaptive FEM for problems with time-dependent domains.

Oberwolfach Report 42/2016, 56-58 pages, Mathematisches Forschungsinstitut Oberwolfach (MFO), 2016. - M. Jahn, T. Klock, A. Luttmann.

Levelset methods (and XFEM) in FEniCS.

Projektbericht, Poster, FEniCS'15 Workshop at Imperial College London, Juni 2015. - M. Jahn, H. Brüning, A. Schmidt, F. Vollertsen.

Energy dissipation in laser-based free form heading: a numerical approach.

Production Engineering - Research and Development, , Springer Verlag, 2013.DOI: 10.1007/s11740-013-0509-8

online at: http://link.springer.com/article/10.1007%2Fs11740-013-0509-8 - H. Brüning, M. Jahn, A. Schmidt.

Process Window For Forming Of Micro Preforms At Different Temperatures.

Advanced Materials Research, 769:173-180, Trans Tech Publications, 2013.DOI: doi:10.4028/www.scientific.net/AMR.769.173

online at: http://www.scientific.net/AMR.769.173 - M. Jahn, A. Luttmann, A. Schmidt.

Finite element simulation for material accumulation and welding processes including a free melt surface.

PAMM, 13(1), 235–236 pp., Wiley, 2013.DOI: 10.1002/pamm.201310113

online at: http://onlinelibrary.wiley.com/doi/10.1002/pamm.201310113/abstract - M. Jahn, A. Luttmann, A. Schmidt.

A FEM simulation for solid-liquid-solid phase transitions during the production of micro-components.

11th International Scientific Conference on Advanced Production Technologies (MMA 2012), 20.09.-21.09.2012, Novi Sad, Serbia.

Proceedings of the 11th International Scientific Conference on Advanced Production Technologies (MMA 2012), 11(1):231-234, 2012. - M. Jahn, A. Luttmann, A. Schmidt, J. Paul.

Finite element methods for problems with solid-liquid-solid phase transitions and free melt surface.

PAMM, 12(1):403-404, Wiley, 2012.DOI: 10.1002/pamm.201210190

online at: http://onlinelibrary.wiley.com/doi/10.1002/pamm.201210190/abstract - E. Bänsch, J. Paul, A. Schmidt.

An ALE finite element method for a coupled Stefan problem and Navier-Stokes equations with free capillary surface.

International Journal for Numerical Methods in Fluids, Article first published online : 6 AUG 2012, DOI: 10.1002/fld.3711 , Wiley, 2012.DOI: 10.1002/fld.3711