Mathematical visualization

| Working Group: | WG Industrial Mathematics |

| Leadership: | Prof. Dr. Dr. h.c. Peter Maaß ((0421) 218-63801, E-Mail: pmaass@math.uni-bremen.de ) |

| Processor: | Dr.-Ing. Jost Vehmeyer |

| Project partner: | |

| Time period: | 01.01.2016 - 30.06.2017 |

Imaging techniques, industrial sensors and the increasing use of computer simulations are leading to continually growing amounts of information and therefore, researchers are often confronted with huge amounts of data. In practice, the data is too large and often too abstract for a direct analysis. Mathematical visualization combines numerics, geometry and computer graphics. On the one hand, visualization supports research and mathematical modeling, and on the other hand, new techniques for computer graphics and scientific visualization are developed. The challenge is to translate data into geometry and give it meaning. For this purpose, the data is transferred into a visual system, where interpretations, analyzes and manipulations are made possible.

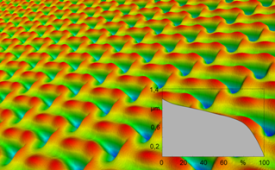

Practical applications can be found in the Collaborative Research Center 747, subproject C2 "Surface Optimization" and subproject T4 "Optimization of Dental Products", where the geometry of micro and macro scale of technical surfaces is investigated. The micro geometry or texture of finished surfaces influences the mechanical and optical behavior of the manufactured component. The surfaces produced by micro milling, with a tool of only 0.25 mm diameter, are the result of a complex interaction of the material and the tool, which was mathematically modeled in the SFB 747. A process understanding is of high technological and economic importance in manufacturing technology. The 3D visualization allows the human eye to gain insight into the microcosm of the surfaces and their kinematic conditions. In particular, with the help of a visual system, the relationships of the occurring geometric surface effects were investigated which could previously only be observed in the experimental field. In the reversal, it was possible to generate geometric features by manipulating machining variables, which in turn make a desired tribological behavior of the component possible.

The visualization of biological processes and tumor diagnostics are other applications that are investigated at ZeTeM. New imaging techniques, like matrix-assisted laser ionization (MALDI) and magnetic particle imaging (MPI) not only provide insights into anatomy, but also into the protein composition of the tissue, which contains much information about health or illness of humans. Superimposing images with established procedures and comparing different stages of biological development is a major challenge. Biological processes are complex and always subject to natural fluctuations, imaging is always afflicted with errors and therefore, the automated processing of the huge amounts of data still leads to many unsolved problems.